CHEMISORPTION ANALYZERS : THE AMI CHEMI FAMLY

AMI-300 Chemisorption Analyzer

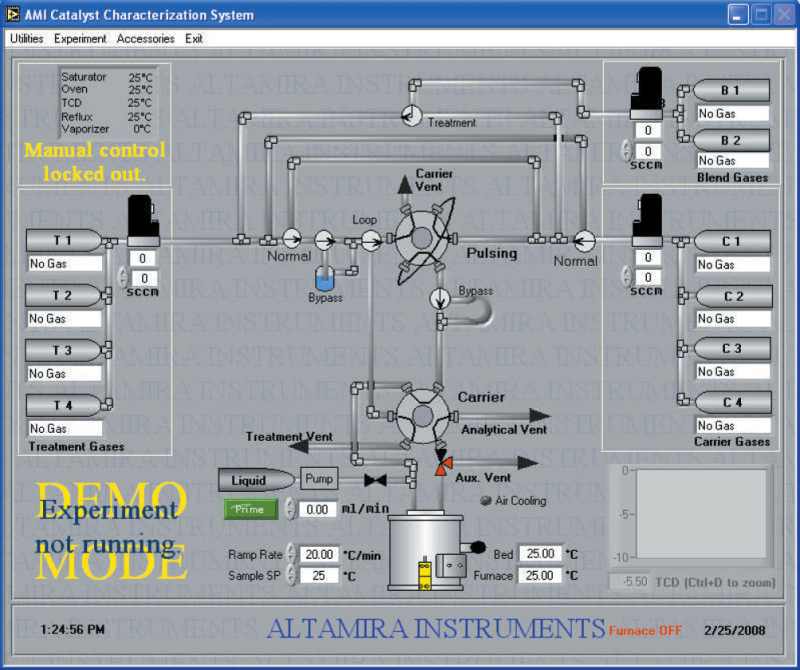

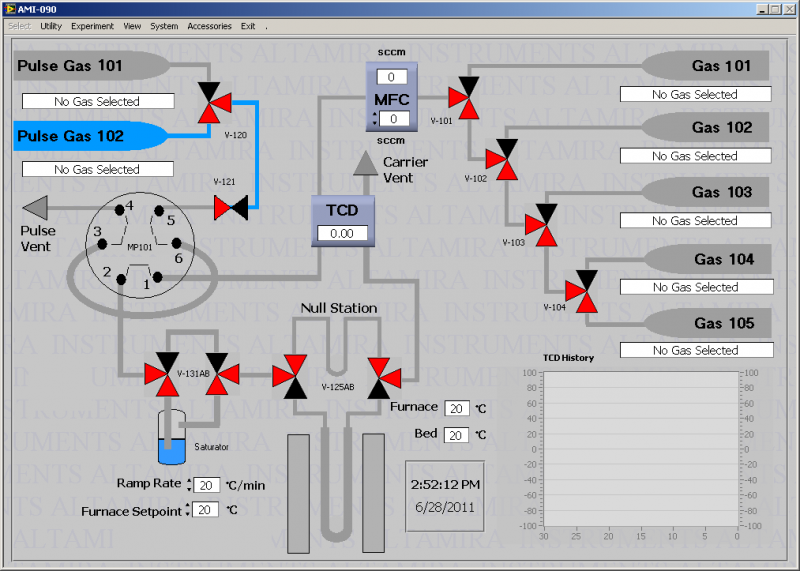

Perform fully automated temperature-programmed and isothermal chemisorption and gas-phase reaction experiments with the latest generation in the AMI family, the AMI-300. Determine metal dispersion, relative activity, adsorption strength, in one third the time of traditional volumetric methods. Analyze the off gas with the standard TCD or integrate a mass spectrometer or other detectors (FID, GC, FTIR) as options. Let us customize the instrument so you can, for example:

(1) also use it as an atmospheric reactor,

(2) carry out lengthy pre-treatments in a separate station

(3) provide fast-switched feed compositions to mimic lean-rich burn scenarios;

(4) provide SSITKA capability, and many more. The leader in automated TPD/TPR/O/TPRx, and pulse chemisorption instruments since 1985, Altamira Instruments is the catalyst researcher’s primary resource for automated catalyst test instruments and bench-scale reactor systems. The AMI series of instruments were the first fully automated chemisorption machines on

The AMI-300 is the latest generation automated chemisorption analyzer offered by Altamira Instruments. Developed by and for catalyst researchers, it and its predecessors, the AMI-1, AMI-100, and the AMI-200, were first in the industry to offer a fully automated system capable of performing all the major dynamic techniques required for fully characterizing a catalyst. The AMI-300 utilizes our proven technology for performing the following dynamic procedures:

- Temperature programmed desorption (TPD) & reduction/oxidation (TPR/O)

- Temperature programmed reaction (TPRx)

- Gas-phase isotherm reaction experiments (standard interal gas-mixing)

- Pulse chemisorption & Catalyst treatment

- Flow BET surface area & Pulse calibration

Up to 99 procedures can be linked together consecutively to provide a complete characterization experiment.

All experimental procedures can be designed and stored for easy retrieval.

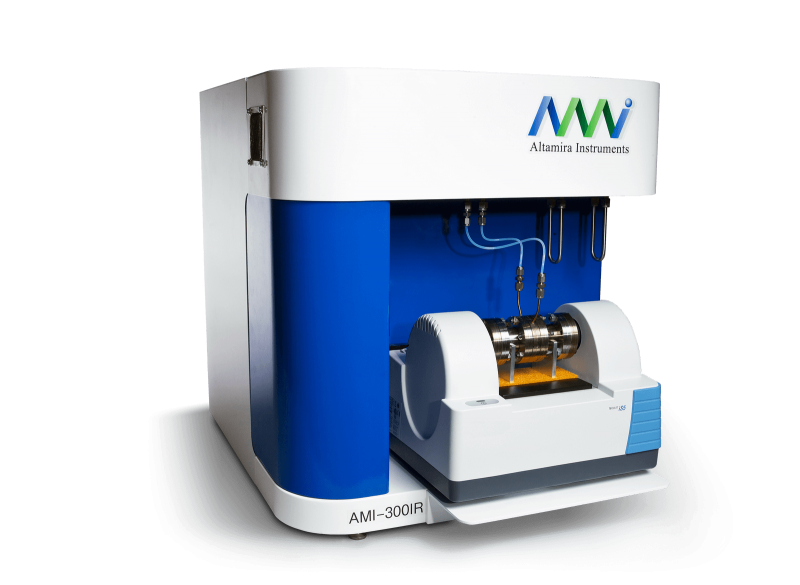

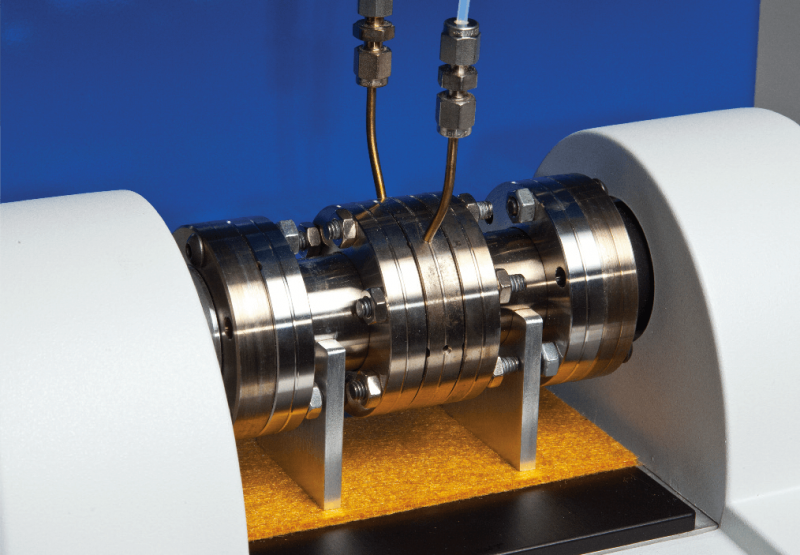

Fully Automatic Chemisorption/TPD by FTIR AMI - 300 IR

Chemisorption and thermal desorption techniques, such as TPD (temperature programmed desorption), have been widely used for the characterization of catalysts. These techniques rely solely on the observation of evolved gases from a catalyst surface as detected by a thermal conductivity detector (TCD) or, in some cases, a mass spectrometer. With these techniques it is possible to learn about the number and strengths of sites but not about the nature of the sites, the type of adsorption, or whether there exist multiple types of sites. In order to overcome this drawback, Altamira has now developed the AMI-300IR which combines all the standard AMI techniques with real-time observation of the catalyst surface by Fourier Transform Infrared (FTIR) spectroscopy. This combination of techniques allows for the direct observation of the adsorbed species and thus expands the knowledge of the nature of the adsorption/desorption process.

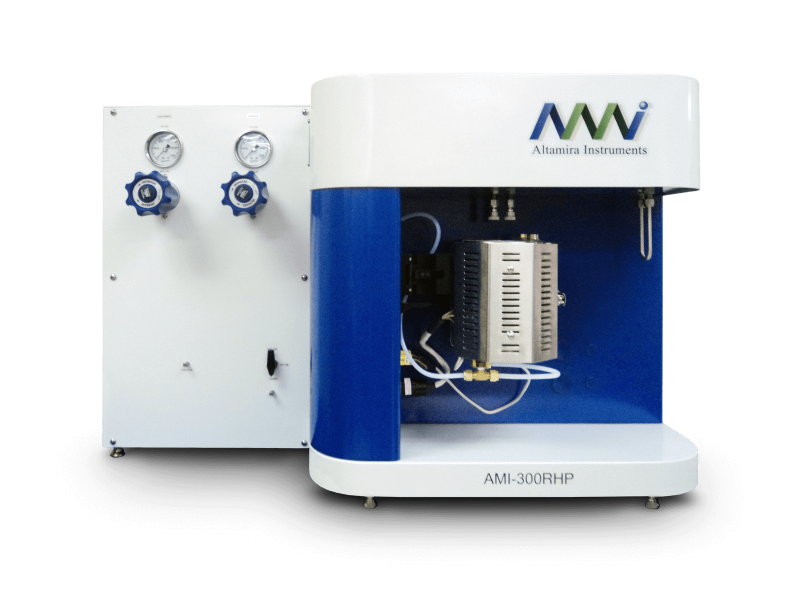

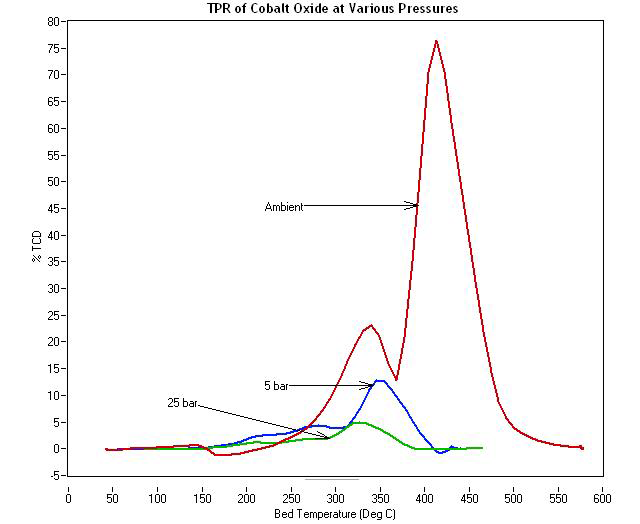

High Pressure Chemisorption Analyzer AMI-300RHP

Based on our successful AMI-300 instrument, the AMI-300HP represents an automated high pressure chemisorption analyzer. The AMI-300HP performs dynamic high pressure temperature-programmed experiments designed to reach 100 bar

(higher pressures available in custom instruments). When integrated with a pump, the AMI-300RHP provides the most sophisticated and automated characterization and micro-reactor instrument in the industry. The sophisticated design allows for the system to also double as a single-station Bench-top reactor.

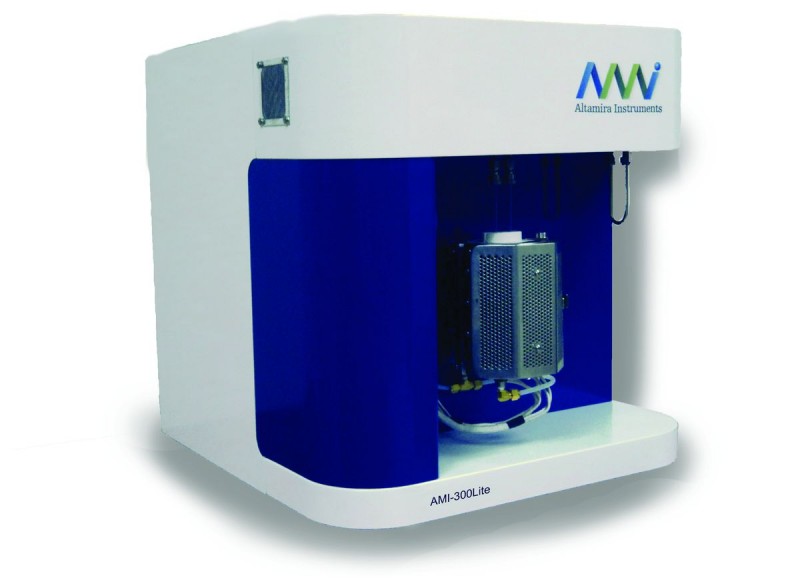

Economic Chemisorption Analyzer

Based on our successful AMI-300 instrument, the AMI-300Lite allows for rapid chemisorption studies in a compact, affordable package. The AMI-300Lite was designed specifically for the price-conscious customers with applications that are more routine or less demanding. As always, full automation and powerful data-handling software assure data accuracy and improve laboratory efficiency.

메인으로

메인으로 즐겨찾기

즐겨찾기